Products

- Commerical Peanut Candy Groundnut Cake Making Machine

- Peanut Brittle Making Machine|Commercial Peanut Brittle Production Line|Peanut Candy Production Line

- Rice Candy Bar Making Machine Price

- Nougat Bar Making Machine For Sale|Nougat Candy Cutting Machine

- Granola Bar Making Machine For Sale

- Peanut Nougat Making Machine For Sale

- Nougat Cutting Machine For Sale

- Peanut Brittle Machine|Automatic Peanut Brittle Production Line|Peanut Candy Machine

- Peanut Brittle Production Line Factory Price

- High Quality Peanut Candy Production Line

- Rice Krispies Treat Machine|Rice Krispies Making Machine|Rice Krispies Production Line

- Puffed Cereal Bar Production Line|Cereal Bar Making Machine|Cereal Bar Production Line

- Nutrition Bar Machine|Grain Bar Forming Machine|Rice Candy Ball Making Machine

- Swelled Rice Candy Bar|Grain Bar Making Machine Supplier

- Protein Bar|Breakfast Cereal|Rice Ball Sugar Production Line

- Coffee Corn Processing Line|Coffee Corn Making Machine|Fried Coffee Corn Snacks Machine

- Caramel Treats Production Line|Sachima Production Line

- Pillow Type Packing Machine|Snack Packing Machine

- Rice Puffing Machine|Cereal Puffing Machines|Rice Air Flow Puffing Machine

- Sugar Cooking Pot|steam jacket kettle

- Sesame Roasting Machine|Peanut Roasting Machine

- Coffee Bean Roasting Machine|Pistachio Nuts Roaster|Sunflower Seed Roasting Machine

- Groundnut Peeling Machine Cost

- Dry Peanut Peeler Machine|Dry Model Groundnut Peeling Machine

- Nut Peanut Drying Machine With Best Price

- Cocoa Bean Peeling Machine Price

- Peanut Brittle Molding Machine|Sesame Brittle Forming Machine|Sesame Making Machine

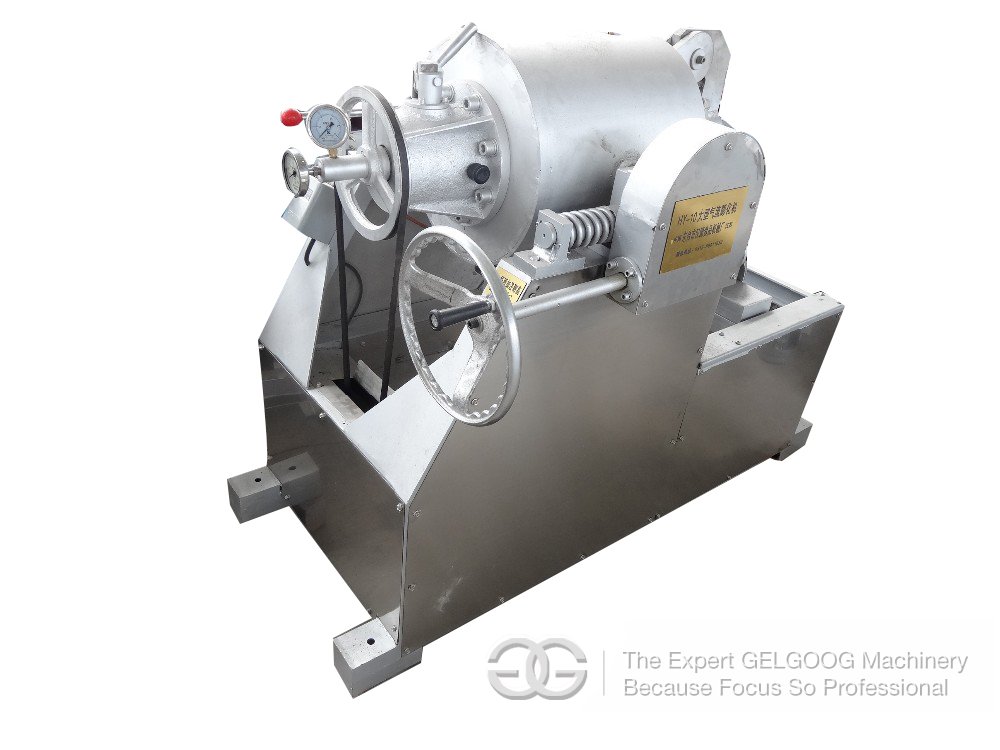

Sesame Candy Machine|Sesame Brittle Cutting Machine|Sesame Bar Making Machine

Sesame Candy Machine|Sesame Brittle Cutting Machine|Sesame Bar Making Machine

- MOQ:1

- Brand:GELGOOG MACHINERY

- Certification: CE

- Supply Ability: 100

- PAY METHOD: WEST UNION L/C T/T CASH

- Warranty Time: 12 Months

- LOADING PORT: Qingdao port

- Country Of Origin: China

Application

The sesame candy forming machine is used to making sesame bar/candy and other snacks.

Main Feature

the sesame candy machine can making different size sesame bars,it is easy operation and high quality.

Features

Introduction:

The sesame bar production line consists of sesame roaster machine, sugar cooking pot, control mixer forming machine and packing machine. Machines are made of high quality stainless steel, it can be used to make caramel treats/sachima, peanut/sesame brittle, nuts cakes and many different products. This roaster machine has a simple structure and it is very easy to operate. This machine uses the round reducer as power, and the chains drive the turning cage to roast the materials. Adopting the way of infrared heating to roast the materials by heat radiation from the pipe heaters. You can choose machine whole made of 304 stainless and machine outer made of carbon steel and inner turning cage made of 304 stainless steel.

The forming machine is first choice for sesame crisp flake slice forming machine by using two- press and one cut for sesame crisp flake with features of stable performance, reasonable structure, being easy to operate and easy to maintain. Automatic packing machine is mainly used for biscuits, bread, moon cake, candy, eggs, sweet potato cakes, caramel treats, daily necessities, hardware parts, cartons or pallets and other solid objects with the packaging rules.

Advantages:

1. High quality, machine is made of stainless steel 304, conform food safety requirement.

2. Working process is simple, only consist of mixing machine, molding and cutting machine. Of course if need other machine, like sugar pot, pillow packing machine, we can supply.

3. Mixing machine is nonstick barrel wall, stir uniform, non-stick pot

4. Machines working is automatic. Between molding machine and cutting machine, there will be conveyor, making processing more easier, easy to operate.

5. Products size can be adjustable. Our machine can customize tray groove and cutter distance to control product size.

6. Automatic control reciprocation, flattened uniformly smooth. Automatic dicer, one time molding, product size, weight keep same.

7. Elegant and beautiful performance, compact structure and durable.

The sesame bar production line consists of sesame roaster machine, sugar cooking pot, control mixer forming machine and packing machine. Machines are made of high quality stainless steel, it can be used to make caramel treats/sachima, peanut/sesame brittle, nuts cakes and many different products. This roaster machine has a simple structure and it is very easy to operate. This machine uses the round reducer as power, and the chains drive the turning cage to roast the materials. Adopting the way of infrared heating to roast the materials by heat radiation from the pipe heaters. You can choose machine whole made of 304 stainless and machine outer made of carbon steel and inner turning cage made of 304 stainless steel.

The forming machine is first choice for sesame crisp flake slice forming machine by using two- press and one cut for sesame crisp flake with features of stable performance, reasonable structure, being easy to operate and easy to maintain. Automatic packing machine is mainly used for biscuits, bread, moon cake, candy, eggs, sweet potato cakes, caramel treats, daily necessities, hardware parts, cartons or pallets and other solid objects with the packaging rules.

Advantages:

1. High quality, machine is made of stainless steel 304, conform food safety requirement.

2. Working process is simple, only consist of mixing machine, molding and cutting machine. Of course if need other machine, like sugar pot, pillow packing machine, we can supply.

3. Mixing machine is nonstick barrel wall, stir uniform, non-stick pot

4. Machines working is automatic. Between molding machine and cutting machine, there will be conveyor, making processing more easier, easy to operate.

5. Products size can be adjustable. Our machine can customize tray groove and cutter distance to control product size.

6. Automatic control reciprocation, flattened uniformly smooth. Automatic dicer, one time molding, product size, weight keep same.

7. Elegant and beautiful performance, compact structure and durable.

Technical Data

| No. | Equipment Name |

Output |

Power (kw) |

Dimension (mm) |

Quantity |

| 1 | Sesame Automatic Roaster | 200kg/h | 24 | 2700*1260*1550 | 1 |

| 2 | Automatic Sugar Cooking Pot | 100L | 15 | 1200*1000*800 | 1 |

| 3 | Temperature Control Mixer | 3-8kg/time | 4.1 | 680*500*800 | 1 |

| 4 | Automatic Forming Machine | 200-300kg/h | 2.2 | 3800*1000*1600 | 1 |

| 5 | Automatic Packing Machine | 50-250bag/min | 2.5 | 4000*950*1450 | 1 |

Other production machine configuration, please contact our advisory details.

Other production machine configuration, please contact our advisory details.

FAQ

1.Q:can I get some samples?and what is the delivery time?

A:we are honored to sent you samples for quality check.for delivery time,10-20 days after confirm the sample order.

2.Q:do you have the products in stock?

A:Yes,we have some model products can supply to you.

3.Q:can I mix different modles in one container?

A:yes,different modles can be mixed in one container,but the quantity of each model should not be less than MOQ.

4.Q:how does your factory do regarding quality control?

A:Quality is priority,we always attach great importance to quality control from the very beginning to the end of the production,every product will be fully assembled and carefully tested before it's packed for shipment.

Related Products

Rice Krispies Treat Machine|Rice Krispies Making Machine|Rice Krispies Production Line

Rice Krispies Treat Machine|Rice Krispies Making Machine|Rice Krispies Production Line Peanut Brittle Making Machine|Commercial Peanut Brittle Production Line|Peanut Candy Production Line

Peanut Brittle Making Machine|Commercial Peanut Brittle Production Line|Peanut Candy Production Line Rice Puffing Machine|Cereal Puffing Machines|Rice Air Flow Puffing Machine

Rice Puffing Machine|Cereal Puffing Machines|Rice Air Flow Puffing Machine Sugar Cooking Pot|steam jacket kettle

Sugar Cooking Pot|steam jacket kettle